For precise metal cutting, turn to Lowes reciprocating saw blades, designed specifically for durability and performance. Choose bi-metal blades, as they combine high-speed steel and carbon steel, enabling them to cut through various types of metal effectively. Look for blades with at least 18 teeth per inch (TPI) to achieve smooth cuts and reduce the risk of blade binding.

Consider the cutting thickness before selecting a blade. If you’re working with thicker metals, go for blades in the 1″ to 3″ range, as they provide the necessary stability and strength. For thinner metals, blades with a lower TPI and a finer tooth configuration will offer greater control and finesse.

Don’t overlook the importance of the blade’s design. Coated blades with a titanium or carbide finish resist heat and corrosion, extending their lifespan during demanding tasks. Additionally, check for compatibility with your specific reciprocating saw model, as some blades feature universal shanks for a convenient fit.

By selecting the right Lowes reciprocating saw blades, achieve cleaner cuts, increase cutting speed, and enhance your overall project efficiency. Equip yourself with the appropriate blade, and experience improved results in your metal cutting endeavors.

- Lowes Reciprocating Saw Blades for Metal

- Recommended Blades

- Blade Length and Compatibility

- Choosing the Right Type of Blade for Metal Cutting

- Comparing Bi-Metal and Carbide-Tipped Blades

- Understanding Blade TPI (Teeth Per Inch) for Optimal Performance

- Finding the Right Balance

- Blade Material Matters

- Maintenance Tips for Longevity of Your Reciprocating Saw Blades

- Cleaning and Storage

- Proper Usage Techniques

Lowes Reciprocating Saw Blades for Metal

For cutting metal, choose bi-metal reciprocating saw blades available at Lowes. These blades feature high-speed steel teeth that provide the durability needed for rigorous metal cutting tasks.

Recommended Blades

Look for blades ranging from 18 to 32 TPI (teeth per inch). The higher TPI count is ideal for thinner metals, while lower TPI works better for thicker materials. The Milwaukee 48-00-1201 is a solid option for cutting various metal types, including aluminum and steel. Its fine teeth accelerate cutting without damaging the material.

Blade Length and Compatibility

Select blade lengths between 9 and 12 inches for versatility. Ensure compatibility with your reciprocating saw model; most blades are standard, but check specifications for a secure fit. Proper installation enhances performance and safety.

Keep a few different blades on hand to tackle different projects efficiently. Regularly inspect blades for wear and replace them as necessary to maintain cutting precision. This approach saves time and improves overall productivity in your metalworking tasks.

Choosing the Right Type of Blade for Metal Cutting

Select a bi-metal blade for cutting metal, as it combines flexibility and durability. These blades typically feature high-speed steel teeth that resist wear while cutting through various metal types, from thin sheet metals to tougher alloys.

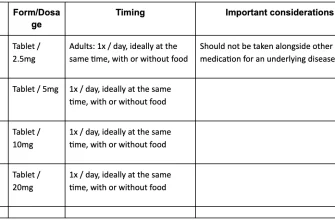

If you’re working with thicker materials, consider a blade with a lower tooth count, around 10-14 TPI (teeth per inch). This design allows for faster cuts while maintaining strength. For thinner metals, opt for blades with a higher TPI, like 18-32, as they provide smoother cuts.

Pay attention to the blade width. Wider blades are more stable for straight cuts, while narrower blades excel in intricate or tight cuts. Look for a blade length that suits your saw and the material you’re cutting; commonly, 12-inch or 18-inch blades work well for most metal projects.

Consider specialized coatings, such as titanium or carbide-tipped options, which enhance cutting performance and prolong blade life. Always check compatibility with your reciprocating saw to ensure optimal results.

In summary, choose a bi-metal blade tailored to your specific cutting requirements, paying attention to tooth count, width, length, and coatings, for successful metal cutting tasks.

Comparing Bi-Metal and Carbide-Tipped Blades

Choose bi-metal blades for their versatility and cost-effectiveness. They combine high-speed steel teeth with a tougher body, making them suitable for cutting a wide range of materials, including metal, wood, and plastic. These blades resist wear and can withstand heat, but they may dull faster when cutting particularly tough metals.

Conversely, carbide-tipped blades excel in cutting hard materials like stainless steel or cast iron. The tips remain sharp significantly longer, offering precision and a smooth finish. However, these blades are less flexible, which can lead to breakage in challenging conditions. For heavy-duty projects or frequent use with hard metal, they deliver consistent performance.

Evaluate your cutting needs when deciding. For occasional tasks and general use, bi-metal blades suffice. If your projects demand cutting through dense materials regularly, invest in carbide-tipped blades. This choice ensures durability and reduces downtime for blade changes, allowing you to complete your work efficiently.

Always consider the thickness and hardness of the materials you plan to cut. Using the appropriate blade enhances productivity and ensures clean cuts without damaging your workpiece. Match your blade selection to your specific requirements for optimal results.

Understanding Blade TPI (Teeth Per Inch) for Optimal Performance

Choose the right TPI for your metal cutting tasks to achieve the best results. For softer metals like aluminum or brass, blades with a higher TPI, typically between 14 to 24, will provide cleaner cuts and reduce burrs. They allow for finer finishes, making them ideal for intricate work.

For harder metals, select blades with a lower TPI, ranging from 6 to 10. These blades are designed to remove material more quickly and handle tougher materials without becoming bogged down. The fewer teeth means larger gullets, which helps clear chips more efficiently and prevents overheating.

Finding the Right Balance

Keep in mind that more teeth help with precision, while fewer teeth enhance speed. Assess your project requirements carefully. If your task involves both intricate cuts and tougher materials, consider using multiple blades to switch out as needed, ensuring optimal performance throughout your work.

Blade Material Matters

Additionally, the material of the blade itself affects performance. Bi-metal blades combine flexibility with toughness, making them suitable for a variety of metal types. Carbide-tipped blades excel at cutting through hard materials, increasing longevity and durability. Always match the blade material to your specific cutting needs for the best outcomes.

Maintenance Tips for Longevity of Your Reciprocating Saw Blades

Regularly inspect your reciprocating saw blades for any signs of wear or damage. A thorough inspection helps identify problems early, reducing the risk of untimely replacements.

Cleaning and Storage

Keep your blades clean after each use. Wipe off any debris or grime with a cloth and a mild solvent. Store blades in a dry place, preferably in their original packaging or a dedicated case, to prevent rust and damage.

Proper Usage Techniques

- Use the appropriate blade type for your specific material–metal blades for cutting metal.

- Maintain a steady pace when cutting; avoid forcing the saw as it can lead to blade fracture or dulling.

- Apply enough pressure to engage the blade without pushing too hard, which can cause premature wear.

Sharpen dull blades when necessary. Investing in a sharpening tool allows you to extend the lifespan of your blades effectively. Keeping a sharp edge not only enhances performance but also makes the cutting process smoother.

- Check your saw’s settings and ensure that the speed is appropriate for the material you are cutting.

- Rotate blades if they have multiple teeth; this helps distribute wear evenly.

Understand the cutting angle. Using the correct angle minimizes stress on the blade and provides cleaner cuts. Adjust your grip to maintain control for enhanced safety and accuracy.

By adhering to these maintenance tips, you can ensure that your reciprocating saw blades remain in good condition, providing you with reliable performance for all your metal-cutting needs.